The coffee shop was a short stop after a moderately long drive and the engine was good and warm, and turning it off gave it a good heat soak. After a 10 minute delay, it would crank with alacrity, but would not start, not even a cough.

After some poking around (testing for mechanical soundness, then the Fuel/Air/Spark trifecta), I determined that the injector wasn't pulsing fuel into the intake, either during priming, nor when cranking. While I was poking around with the hood open, trying to wiggle electrical connectors and divine an obvious point of failure, the engine started (after about 30 minutes of hood-open cooling).

Back at the hanger, I checked the (slightly useful) Haynes manual, asked google, and searched the Fiero, S-10, and a-body.net forums. Sadly, a few folks had the exact same symptoms I was experiencing but no one had posted a sure solution.

Examples:

- 87 Cutlass Ciera won't start when hot

- Mystery GM car from similar vintage

- 88 Iron Duke Fiero Hot Start Failure

The fuel delivery system in the TBI Iron Duke has a few parts that have to work together.

- Tank Fuel Pump (I could hear it turn on -it worked)

- Fuel Pump Relay and Fuse (If the pump works, they work, obviously)

- Oil Pressure Sensor/Switch (keeps the pump running when the engine is running, gathered it works since the engine runs fine, it was starting.)

- Fuel Injector (unknown - no squirting when cranking)

- Ignition Module (unknown - no ignition when cranking)

- Crank Sensor (unknown - no ignition when cranking)

- Engine Temperature Sensors (Couldn't test in the parking lot, but easy to test in the driveway, about 1000 ohms at 45C: about as warm as you can keep your hand on without feeling burning.)

- Throttle Position Sensor (unknown)

- ECU (Unknown, but hot start failure would not seem to indicate and ECU issue that would not manifest elsewhere).

The easiest part to remove and bench test is the throttle body. Close inspection showed that the weather seal of the injector harness had denatured, leading me to wonder if there was an internal short in the connector. Removing the connector and inspecting the contacts showed this could not be the case.

Denatured weather seal connector: gooey!

Throttle body exposed with fuel lines removed.The throttle body is held on by the threaded rods. The star drive screws hold the two halves of the TBI together.

Top of the throttle body on the work bench.

Fuel pressure regulator and idle air control (IAC) valve. Also vacuum ports for the evap canister, MAP Sensor, and EGR valve.

Throttle position sensor, fuel ports.

Bellcrank side of the throttle body.

You can sea dust/carbon on the bottom of the throttle body gasket where air is leaked into the intake by the idle air control (IAC) valve.

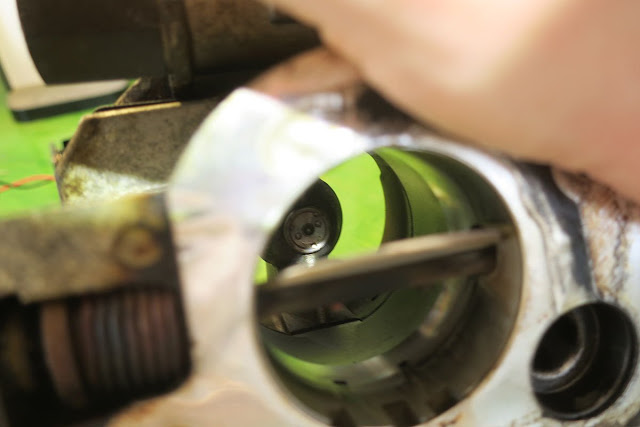

A look at the business end of the injector through the butterfly.

The TPS connector is cast in an off-angle to make it easier to plug in. Nice work, GM.

Injector freed from the throttle body. No particles or scud. O-rings look perfect. This looks like a happy injector.

Injector valve stem and face. The injector looks like it's spot-welded together, so I did not try to take it apart. Besides, the screens looked very clean.

Fuel pressure regulator spring and pretension housing removed. Clean and no corrosion.

Fuel pressure regulator diaphragm and sealing surfaces. Spotless. My cars fuel system is clean! (At least, past the filters)

A view of the backside of the fuel pressure regulator sealing plate. No corrosion.

Throttle body passages. Facing towards the exit.

Fuel pressure regulator bulkhead. Clean and shiny.

Testing the throttle position sensor with an arduino. My worry had been that when warm, the TPS would send a throttle wide open signal, thus telling the ECU to NOT inject fuel. In the event the engine is flooded, one can hold the throttle open all the way, and the ECU will keep the injector off, allowing the engine to evacuate the excess gas.

The TPS (Airtex 5s5008) puts out a 0-5V linear signal that is easily measured with an arduino or volt meter. The arduino's ability to send data to a PC where it could be logged and plotted showed that the TPS had a smooth, jitter free response. Not the problem.

Fuel pressure can be modified by moving this set screw. But why?

Where the throttle body attaches to the intake manifold. Note I scraped all the denatured rubber of the injector harness.

So, none of these provided any obvious link to the random hot start failures. The throttle body seemed fine and there was fuel pressure. That mean the next place to check was the DIS and the crank sensor.

Part Dux: Oldsmobile Cutlass Cierra/GM 2.5L I4 TBI - Won't Start Hot Troubleshooting 2: DIS and Crank Sensor

What is the fuel pressure while cranking cold compared to cranking hot.

ReplyDeleteIt should basically be the same. The system just has a single pressure regulator in the trunk. It's very low pressure, IIRC 10-20 PSI, 15 nominal. Should be mostly constant. That being said when starting fuel pressure might be lower. The computer primes the system for a second or two, but then only pulses the pump when it detects the crankshaft turning.

DeleteOh, I see what you're asking. I don't know how to test the pressure behind the regulator in the TBI unit.

Delete