Newsflash: the car may have been fine.

The core issue was that when the gas tank on my 1990 Volvo 740 was below about 1/4 tank, a pronounced, irregular tone would often develop, coming from the fuel tank. If you say "Wahhhhhh-wah-wah-wah-wahhhhhhhh" you'll approximate it well. Like this video, except lower pitch.

The brickboard FAQ suggested either the in-tank pump for the fuel pressure regulator (FPR). The situation seemed like a dying in tank pump as described by others, so I elected to replace it, as it seemed like it would be just as easy to replace it as test it. Sadly, I was wrong on the last point.

Getting to the pump on the 740 wagon requires completely lowering the rear seats, removing three bolts retaining a floor panel, then lifting and sliding the panel foward to unhook it from two brackets on the floor. The panel was designed to move freely, but a glob of adhesive from manufacturing had gotten trapped under it, and I had to pry it up on all sides to break it free enough to allow it to slide forward. It's plywood, so it could be fixed pretty easily if it got damaged.

Under the panel is an access door to the fuel tank piping and electronics assembly. In the picture below you can see it's position in the car. It also shows how I used a strap wrench to unscrew the collar.

View of the piping and wires going to the tank. The two big pipes at the top of the image are the fuel in and vapor return, the two on the bottom are fuel to engine (upper pipe with screw clamp) and fuel return (lower pipe with spring clamp). The thin hoses are for vapor recovery (charcoal canister). The wires go between the big hoses and enter the tank through a bulkhead. This IS NOT a connector! Do not pull on the plastic to try to remove it from the sender unit. The the wires must be unplugged in the body of the car and fished out.

Every clamp on the unit was so rust it had to be cut off. For some reason volvo couldn't be bothered to install stainless parts here.

I cut the clamps with a low speed rotary tool to keep the sparking to a minimum. When the hoses are intact and connected, there isn't any fuel vapor, but it still made me nervous. On the way out, I re-assembled it with new stainless steel clamps.

After removing the hose clamps, I disconnected the pump power and sender cable. It's the black jacketed wire in the image below and goes into the driver side wiring loom in the back of the wagon. It's under the rear seat and covered by a couple of trim panels. I think the other cable with the box in the middle is the speedometer. I had to loosen the brackets supporting the filler pipe and cut a bunch of cable ties to get everything free. Then I fished it out of the body so the sender unit could be completely removed.

After removing all the hoses, (some of which were dry-rot and needed replacing) I loosened the collar with a strap wrench. After this, the sender can be gently pried out with big screwdriver. It has to be rotated during removal to lift the pump and float over the fuel tank baffles.

Mine was pretty rusty. I gently brushed it off and sprayed it with rust reformer paint when I put it back together.

A volvo part number

The pump and connection tube looked fine. Some other owners have complained that this hose had spilt and started leaking.

Backside of the wiring bulkhead. See? I told you it wasn't a connector.

Blow out pump sock.

I got the Dephi pump to replace the OE VDO pump. Basically because the delphi had a nice looking kit. Sadly, the kit did not have the filter sock!

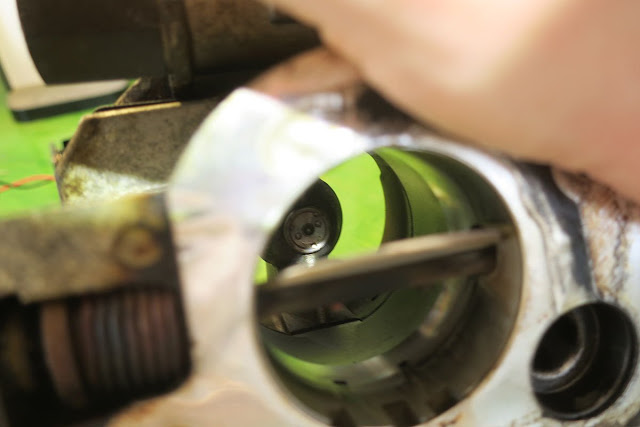

The inside of the VDO pump

The delphi pump has an extra lip, I had to modify the pump holder for it to fit. The delphi has different vane geometry.

The new pump installed.

I couldn't find a new sock at my local parts store for the Volvo, but I remembered the sock for my 1990 Oldsmobile cutlass ciera looked about the same, and they had a few of those. Turns out its a wee bit bigger.

Between tasks, I tried the old pump in a tank of water. It pulled about 1 amp and gave a smooth, even tone that matched the general tone I heard when the fuel was low. It also seemed to push fluid strongly and consistently. It's hard to believe the pump was having problems from this test, though it would not likely overheat in a gallon of water. I made a note to replace the FPR after this test, as it could be the source of the issue. Fortunately, the FPR is less likely to leave the car dead on the side of the road.

The fuel filler pipe. Only installs one way.

The part number of the fuel tank collar. I had a lot of problems cross threading it and I was worried it would break. Annoyingly, this appears to be the PN for the whole sender.

Re-assembled. I cleaned the rust from the edges of the hole and painted it with rust reformer.

In retrospect, I should have just pulled the fuel return line and measured the discharge rate and watched the current draw at the connector with the ammeter. It was a huge investment of time and effort to cut clamps and replace fuel tubing that got damaged during removal. Additionally, replacing the FPR is a comparitively easy task. It seems like testing those two cases before replacing the in tank pump is a better route.

In the end, it's unclear if the new pump is much better than the old pump. The new pump is silent when running, and the car seems like it has a prompt hot-start now.

I also wonder if, for the effort, it would have been better to switch the tank pump to a high pressure pump like a Walbro 255 or 350. I've read a couple of forum posts about it:

https://www.matthewsvolvosite.com/forums/viewtopic.php?t=89760. Overall it sounds like simpler system.